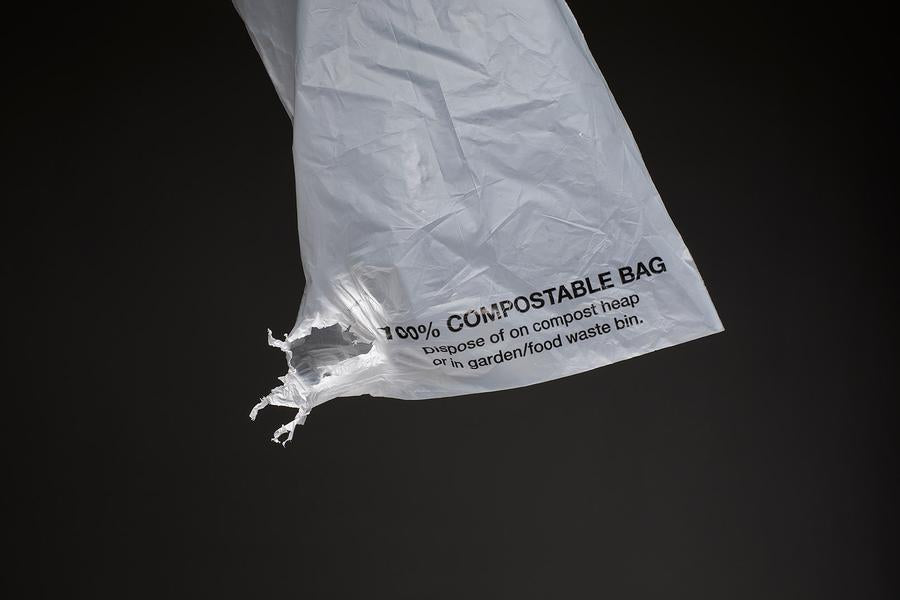

The challenge with single use plastic

At Pacsafe it’s our passion to travel, plan that next adventure, find that pristine beach in Indonesia, explore that remote island off the coast of India, hike the Inca trail, or dive the Great Barrier Reef. When I started to travel over 30 years ago, it was different, Magnus McGlashan, CEO of Pacsafe says, you could travel and never see any plastic in the wilderness, but things have changed. Wherever you go it appears as a sore eye. As a company we believe that travel is one of the most exciting things you can do as a human being, and it’s our obligation to do whatever we can to make the planet a beautiful place to travel for generations to come. Therefore, we have embarked on a different type of journey, to remove all virgin plastic from our supply chain by 2025.